Janice: What led you to studying Computer Engineering?

Hunter: To start, when it was my senior year in high school, I was interested in studying

software and hardware. Choosing Computer Engineering was perfect for me though as

I always wanted to pursue robotics. However, what I’ve learned is that no matter what

major you are, it depends on what you want to do. If you really want to do something

you will go out of your way to pursue it.

Why did you choose to study at Stony Brook University?

I personally chose Stony Brook because it is known to be one of the best engineering

schools in New York. I went to Georgia for high school in a rural area so by my senior

year in high school, I decided I wanted to experience other parts of the US and experience

the city/urban life.

This only had a slight influence but I also read The Great Gatsby in high school which

brought up Long Island a lot.

What is a fun fact about yourself?

I’ve actually never taken a formal Japanese class and I studied it on my own. Like

most people, it started with anime and I would watch Japanese videos that the youtube

algorithm showed me. I ended up learning more than enough unintentionally. I think

it is really meaningful that you can learn a lot even when it is not intentional.

What do you like to do in your free time outside of working, any hobbies?

Outside of work I like building plastic robot models. It’s surprising how dedicated

the modeling community is as they have a wide range of models and shop owners are

very passionate about it despite it not bringing in a lot of profit.

Did you always plan on becoming a robotics engineer, or work at Mitsubishi?

No, not at all. It started during my senior year for the senior design project where

I was working on an autonomous driving car. The project used a Robot Operating System

(ROS) and funnily, it ended up being my job. But in general, ROS is a common open

source interface that is used to control robots. Previously, each robot company had

their own language but with ROS you can universally control them. This ended up overlapping

with Mitsubishi which is how I ended up working there.

How did you come across the opportunity to work at Mitsubishi Electric?

So there is this annual conference called the Boston Career Forum which has 50 years

of history for both Japanese and American companies. The goal is to recruit bilingual

students and I happened to try it out. At the time my Japanese was not that good,

but I still interviewed for 8 companies in the span of 3 days. I had 7 interviews

in Japanese but they didn’t end up that well, however, by the last interview I used

my previous failures as practice materials which improved the last interview process

significantly. Of course, the last interview happened to be with Mitsubishi.

As a robotic engineer, what does your usual work look like?

In general, I have a lot of flexibility as long as I keep the core time which is usually

10:00 AM to 2:30 PM. I prefer to show up to work a bit earlier at 7:30 AM rather than

the usual 8:30 AM to give myself a quiet hour to summarize the previous day’s work,

decide on what to work on today, update my calendar accordingly, and study Japanese

business terms.

Around 8:30 everyone starts coming in and that’s when we have a team meeting about

who will handle what work followed by 2 hours of focused work time. We usually have

another meeting before our lunch break, and after lunch I usually interface with the

other global teams such as the Singaporean team. Later in the afternoon there’s usually

more meetings or informal discussions among the team members regarding specific decisions.

You mentioned that you are working on industrial robot arms (specifically the software

side), how will these robot arms be used?

So the robot arms are controlled by a Program Logic Controller (PLC), so it is an

embedded system that controls factory switches. There are many applications but it

is mainly used in factories, Mitsubishi is the manufacturer. The system integration

is based on the customer’s needs, as they choose the manufacturer and program. Most

factories have limited technical knowledge so we have to design the interface in a

way that all technical levels can be able to use it. We also have to balance safety

and ease of use and understanding.

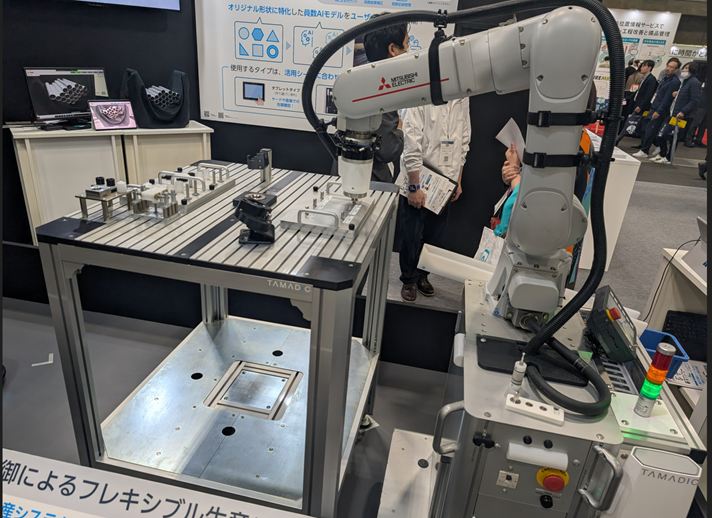

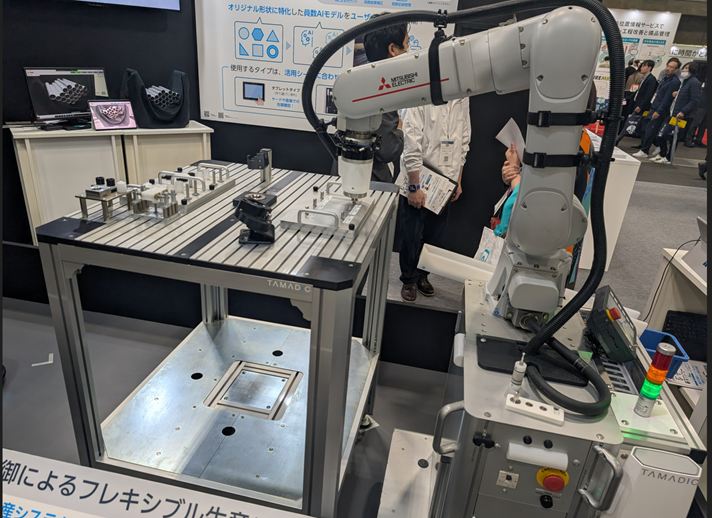

Smart Manufacturing booth

Smart Manufacturing booth

From China to America and now Japan, those are really big environmental changes. Were

you always prepared to make such big changes? Was it hard getting used to?

I definitely did not prepare to move to Japan before the later half of my senior year,

but I saw a great opportunity and decided to take it. I was always assured that I

would figure it out, I already did it once by moving to the US and it was much rougher.

At the time it was already my 9th or 10th year in the US and while I felt like I really

adapted to American life, I didn’t want to block myself from understanding life from

other parts of the world and living through their perspectives. I wanted to experience

more countries in general and Japan came around. I didn’t think it would be easy but

at that time I felt like it was the best timing to see if I could adapt to another

country.

What was your post-grad like? Did you immediately start working?

I had around 3 months after graduation, so I spent that time with my family and visiting

my friends around the US before leaving for Japan.

Were there any resources you found helpful during your time at Stony Brook University?

(i.e. finding a job, studying, etc.)

In general, the CEAS advisors are very helpful for things like what courses to take

and certain career path decisions. Stony Brook is a big school so it is really helpful

to have someone navigate you to the different resources.

I would also say that take the opportunity to learn something thoroughly while you

are on campus with professors and students. Now that I’ve started working, it is very

hard to focus on learning something new as life happens, there are many interruptions,

and it takes a lot of determination.

Do you have any advice for those who are looking to go into a similar field (robotics)?

Troubleshooting with an AI agent

Troubleshooting with an AI agent

Robotics is a vast field, but you could start by learning about the 6-axis or 4-axis

arm. The current trend is that hardware is reaching its end so there is less and less

to improve on in terms of hardware. You probably won’t be seeing any big changes.

I think learning the common interface like ROS would be helpful but there’s also a

long way ahead. I would say make sure to keep the foundational knowledge about robots

(such as mechanical, kinematics, and motion planning), but also keep your options

open with the newer technologies (such as behavioral trees and sensor fusion). There

are a lot of things coming but it won’t reach the actual factory quickly as it is

a very slow adoption. That’s because the equipment in factories have long lives.

In general, despite the rising AI use and trends, the stuff we learn is not changing

so focus on the basic skills to define problems and keep your foundationals.

Now that you have spent some time working at Mitsubishi, how do you feel?

Something I’ve noticed is the general manufacturer culture can be quite strict with

their adherence to rules. The reason why they can produce such high quality products

so consistently is because they are adamant to a lot of rules, but sometimes these

rules are cultural and not rational. At the same time, this means they are weaker

when it comes to questioning why certain processes have to be like this. This creates

less opportunities for improving things even though there is high consistency. For

a factory, they want things to be the same for as long as possible despite the new

software and frameworks that are introduced every few years. These products have such

a long life that Mitsubishi still supports products they made 20 years ago. This is

something that I view as a strength and weakness as the manufacturing industry is

slow to adopt but still highly advanced.